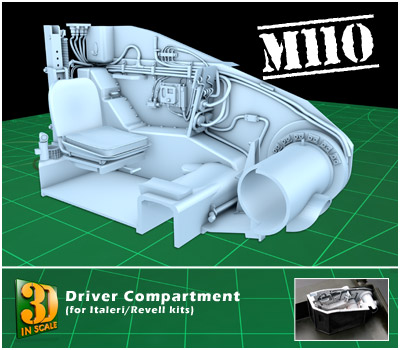

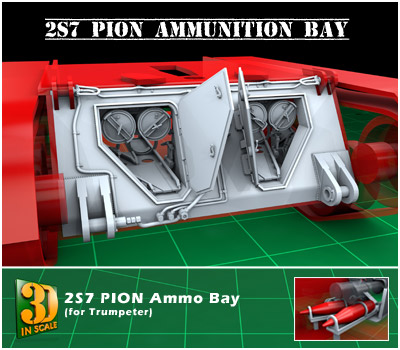

3D IN SCALE designs highly detailed, 1:35th scale,

conversion sets for military modeling. They are made

available for sale thru Shapeways. This 3D printing

company is responsible for production, shipping and

service. Ordering on this website will redirect you to the

Shapeway site.

We are sorry to inform you that we are not able to

include a instruction sheet in your order. Download

buttons can be found thru-out this website. Find the

desired product and click the 'instruction sheet' button.

We can guarantee our designs are highly accurate. Due to the nature of ordering and method of production we have no control over the actual print quality. This is caused by the way 3D printing works. It is also Shapeways responsibility, as the producer, to deliver a constant quality. If you are not satisfied with the delivered product, please contact Shapeways on service@shapeways.com.

Shapeways introduced a material some time ago (Frosted Extreme Detail (FXD)). It prints in a smaller layer thickness and therefore gives a smoother surface.

Some of our products can be ordered in this material but not all. This is because the material has a smaller printing surface of only 5x5 cm and some designs will not fit within these boundaries.

Please know that price of this material is higher (+80%) and ordering designs in this material will be more expensive. The price difference is mostly due to the increase in printing time.

Some of our products can be ordered in this material but not all. This is because the material has a smaller printing surface of only 5x5 cm and some designs will not fit within these boundaries.

Please know that price of this material is higher (+80%) and ordering designs in this material will be more expensive. The price difference is mostly due to the increase in printing time.

Working with 3D printed (resin) material:

The 3D material used is brittle and may break when

handled incorrectly. Take care in removing parts from the

frame. Some parts have been hollowed out to reduce

printing costs. Holes are placed out of site and can be

filled with modeling putty or plastic sheet.

3D printing of parts and conversion sets is done with a

wax-like support material. Due to this production method

a wax residue can remain on the parts. Cleaning them is

not difficult but necessary: Remove parts from the frame

and clean them thoroughly using a soft brush and water

and dishwashing fluid. It is also possible to use a

ultrasonic cleaner with water. Redo cleaning process

until water remains clear. A heavier cleaning can be

done with white spirit or alcohol.

Use enamel based paint or something like thinned down

Mr-surfacer (1000) for the first paint layer. This seals any

3D printing residue that might be left from the printing

process. When left unpainted the 3D material may start to

‘sweat’ and cleaning must be redone.

Working with 3D printed material is simular to working

with cast resin. Heated parts can be straightened (not

over 80 oF) and parts can be glued with superglue.

NOTE: discoloration may occur over time to uncleaned and/or unpainted parts. This will NOT influence the material quality. Please clean thoroughly or redo cleaning.